Brand recognition depends on perfect color consistency, yet many hair dryer manufacturers struggle with color variations that damage retail relationships. When plastic housings shift from deep black to grayish tones across production batches, distributors notice immediately—and your brand reputation suffers from perceived quality inconsistencies.

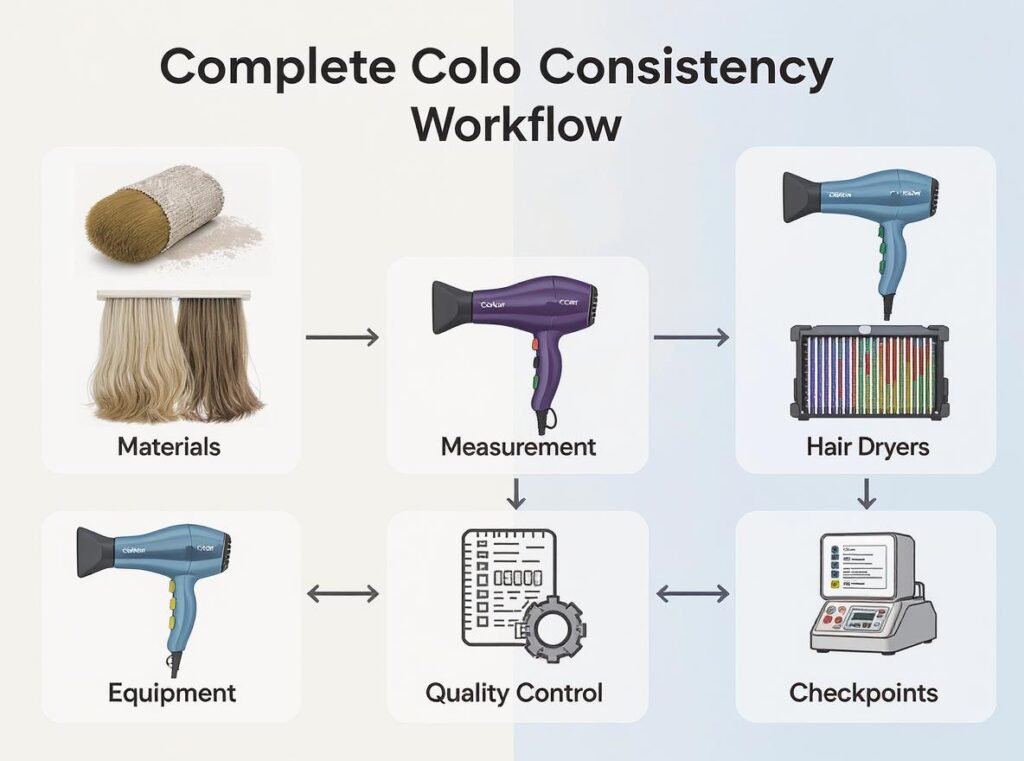

Factories ensure consistent color matching for branded dryers through closed-loop systems combining CIELAB color measurement (targeting ΔE ≤0.8), masterbatch formulation controls, precision injection molding parameters, real-time spectrophotometric monitoring, and ISO 3664-compliant lighting inspection protocols. Professional manufacturers achieve Cpk ≥1.33 process capability through environmental controls and comprehensive material traceability.

Understanding these advanced manufacturing protocols will help you select suppliers who deliver the brand-accurate color consistency your wholesale customers demand.

Table of Contents

ToggleWhat Are the Scientific Foundations of Color Consistency in Hair Dryer Manufacturing?

Color consistency in hair dryer manufacturing relies on precise scientific measurement and control systems that translate marketing color swatches into millions of identical commercial units. Professional manufacturers understand that subjective visual assessment cannot achieve the tolerances required for premium brands.

The scientific foundation uses CIELAB color space coordinates (L, a, b) to define lightness and chromatic axes, with ΔE calculations quantifying color differences. Modern tolerancing employs CIE ΔE₀₀ or CMC 2:1 ellipsoids for better visual correlation, while metamerism testing under multiple illuminants prevents color matching failures.

CIELAB coordinates provide device-independent color measurement essential for consistent results across different equipment and manufacturing locations. The ΔE formula ΔEₐᵦ = √[(ΔL)² + (Δa)² + (Δb*)²] quantifies the distance between two colors, with values below 1.0 representing barely perceptible differences.

Key measurement principles include:

• L axis: Lightness scale from 0 (black) to 100 (white)

• a axis: Green-red chromatic scale with negative values indicating green

• *b axis: Blue-yellow chromatic scale with positive values indicating yellow

• ΔE tolerances**: Professional manufacturers target ≤0.5 for premium brands

Metamerism represents a critical challenge where two parts match under one light source but fail under another. Controlled-lighting booths simulate D50, D65, fluorescent, and LED sources to detect this defect before products reach retailers.

Professional color measurement requires calibrated spectrophotometers with NIST-traceable certificates updated within 12 months to maintain accuracy baselines throughout production cycles.

| Color Science Parameter | Measurement Range | Professional Target | Impact on Consistency |

|---|---|---|---|

| ΔE Tolerance | 0.1-3.0 | ≤0.8 | Direct color matching |

| L* Lightness | 0-100 | Brand-specific | Brightness consistency |

| CIELAB Coordinates | ±128 each axis | Precise specification | Hue accuracy |

| Metamerism Index | 0-5 scale | <1.0 | Multi-light matching |

How Do Different Coloring Methods Impact Manufacturing Consistency?

Hair dryer manufacturers employ various coloring methods, each offering distinct advantages and limitations for achieving consistent results across high-volume production runs. Understanding these methods helps wholesalers evaluate supplier capabilities and set realistic quality expectations.

Primary coloring methods include custom compounded colored resins (ΔE ≤0.5), masterbatch concentrates (ΔE ≤0.8), liquid color additives (ΔE ≤1.0), in-mold decoration, and secondary painting processes. Custom compounding delivers superior consistency but requires high minimum orders, while masterbatch systems offer flexibility with acceptable tolerance ranges.

Custom compounded colored resins provide excellent batch-to-batch uniformity by pre-mixing pigments with base polymers at the supplier level. This method achieves the tightest color tolerances but typically requires minimum orders exceeding one ton, making it suitable for high-volume standard colors.

Masterbatch concentrates offer the most common approach for hair dryer manufacturing, providing good consistency with flexible minimum order quantities and easy shade adjustments. However, poor pigment dispersion can create streaking defects if injection molding parameters aren’t properly controlled.

Manufacturing method considerations include:

• Custom compounding: Best consistency but high MOQ requirements

• Masterbatch systems: Balanced approach with moderate tolerances

• Liquid additives: Fast changeovers but complex cleanup procedures

• In-mold decoration: Photographic effects with film adhesion challenges

Quality control protocols must adapt to each coloring method. Custom compounds require incoming material verification, while masterbatch systems need dispersion monitoring and ratio control throughout production.

Liquid color systems enable rapid production changeovers and reduced inventory but demand precise metering pumps and viscosity control systems that increase equipment complexity and maintenance requirements.

What Injection Molding Parameters Critically Affect Color Uniformity?

Injection molding parameters directly determine color uniformity across hair dryer components, with even minor variations creating noticeable differences that compromise brand consistency. Professional manufacturers implement precise parameter control protocols to maintain repeatable color results.

Critical injection molding parameters affecting color uniformity include melt temperature control (±5°C tolerance), residence time management (<6 minutes for ABS), back pressure optimization for pigment dispersion, screw design matching, and mold temperature consistency (60-70°C for ABS housings). Hot-runner balance prevents gate-to-gate hue differences exceeding 0.7 ΔE.

Melt temperature represents the most critical parameter affecting color consistency. Overheating accelerates pigment degradation and causes yellowing in ABS/PC alloys commonly used for hair dryer housings. Maintaining temperatures within resin supplier specifications (typically 220-260°C for ABS) prevents thermal damage while ensuring proper flow properties.

Residence time control prevents thermal degradation during processing. Excessive dwell times above six minutes for ABS promote thermal oxidation and create color streaking, while insufficient heating fails to achieve complete pigment dispersion.

Parameter optimization strategies include:

• Temperature profiling: Zone-by-zone barrel heating control

• Pressure management: Back pressure settings for masterbatch dispersion

• Screw selection: Compression ratios matched to material flow characteristics

• Cooling uniformity: Consistent mold temperatures across all cavities

Screw design significantly impacts color quality through pigment mixing effectiveness. Mismatched compression ratios trap pigment agglomerates, creating visible color swirls and inconsistent appearance across molded parts.

Hot-runner systems require careful balance to prevent gate-to-gate color variations. Imbalanced flow creates temperature differences that manifest as hue shifts exceeding acceptable tolerances on multi-cavity family tools used for hair dryer component production.

| Parameter | Acceptable Range | Color Impact | Control Method |

|---|---|---|---|

| Melt Temperature | ±5°C from target | Pigment degradation | Zone controllers |

| Residence Time | <6 minutes | Thermal oxidation | Cycle optimization |

| Back Pressure | 10-15% of injection | Dispersion quality | Pressure feedback |

| Mold Temperature | ±2°C uniformity | Gloss variation | Circulating systems |

What Advanced Quality Control Systems Detect Color Variations in Real-Time?

Modern hair dryer manufacturing facilities employ sophisticated quality control systems that detect color variations instantaneously, preventing defective products from reaching customers while maintaining efficient production speeds and minimizing waste.

Advanced quality control systems include benchtop sphere spectrophotometers for lab standards, inline non-contact spectrophotometers with 200ms scan rates, multi-angle spectrophotometers for metallic finishes, controlled-lighting booths meeting ISO 3664 standards, and integrated color QC software managing 100,000+ measurement records with automatic trend analysis and SPC alarms.

Benchtop sphere spectrophotometers like the X-Rite Ci7860 provide 0.01 ΔE resolution for master sample verification and incoming material validation. These laboratory-grade instruments establish color standards and verify masterbatch consistency before production begins.

Inline spectrophotometer systems such as the ERX-130 perform real-time color monitoring with sub-second response times, automatically triggering alarms when measurements exceed preset tolerances. These systems integrate with injection molding controls to stop production immediately when color drift occurs.

Quality control technology hierarchy includes:

• Lab spectrophotometers: Master standards and incoming material verification

• Inline systems: Real-time production monitoring with automatic feedback

• Multi-angle units: Effect pigment measurement for metallic components

• Lighting booths: Visual metamerism detection under multiple illuminants

Professional lighting booths meeting ISO 3664 standards provide controlled illumination for visual inspection and metamerism detection. These systems simulate retail lighting conditions including D50, D65, TL84 fluorescent, and modern LED sources.

Color QC software platforms integrate measurements from multiple instruments, creating comprehensive databases that track color performance over time. Statistical process control algorithms identify trending issues before they become major problems, enabling preventive corrections.

Factories targeting premium brands typically maintain inline ΔE targets ≤0.6 and implement automatic line stops at 1.0 to prevent defective products from reaching assembly operations.

How Do Environmental Controls Maintain Color Stability Throughout Production?

Environmental factors significantly influence color consistency during hair dryer manufacturing, creating cumulative effects that result in noticeable color differences across production batches. Professional manufacturers implement comprehensive environmental control systems to minimize these variations.

Environmental controls maintaining color stability include climate control systems (25±2°C, 45±5%RH), air filtration preventing contamination, UV-controlled lighting meeting SDCM ≤3 uniformity standards, material storage temperature management (<40°C), and desiccant systems controlling moisture absorption in hygroscopic polymers to prevent hydrolysis color shifts.

Temperature control affects multiple aspects of color consistency, from material storage through final inspection. High storage temperatures above 60°C accelerate photooxidation, while ABS materials turn amber above their glass transition temperature of 105°C.

Humidity management proves particularly critical for hygroscopic polymers like PA and PET used in specialized hair dryer components. Moisture absorption causes chain hydrolysis, shifting color properties and creating surface splay defects that compromise appearance quality.

Critical environmental parameters include:

• Temperature stability: Production areas maintained within ±2°C tolerance

• Humidity control: Relative humidity managed at 45±5% to prevent material degradation

• Air quality: Filtration systems removing contaminants affecting color

• Lighting standardization: Factory illumination meeting color evaluation requirements

UV exposure during storage and handling breaks chromophores in plastic components, with blue pigments aging fastest while red pigments demonstrate better stability. Outdoor shipping requires UV-stabilized masterbatch formulations and HALS additives to maintain color integrity.

Factory lighting systems require careful attention during LED retrofits, as spectral power distribution changes can alter color perception and measurement. Facilities upgrading to LED illumination must recalibrate ΔE limits and may need masterbatch reformulation to maintain retail color matching.

Material storage protocols specify maximum temperatures and require desiccant protection for moisture-sensitive resins. Proper storage prevents color degradation before processing while maintaining consistent material properties throughout production runs.

| Environmental Factor | Control Range | Color Impact | Monitoring Method |

|---|---|---|---|

| Production Temperature | 25±2°C | Thermal stability | Continuous logging |

| Relative Humidity | 45±5%RH | Hydrolysis prevention | Hygrometer systems |

| Material Storage | <40°C | Oxidation control | Temperature alarms |

| UV Exposure | Filtered lighting | Chromophore protection | Light meters |

What Role Does Strategic Material Selection Play in Color Consistency?

Material selection forms the foundation of consistent color matching in hair dryer manufacturing, directly determining achievable tolerance ranges and long-term color stability. Understanding material properties helps wholesalers evaluate supplier capabilities and set realistic quality expectations.

Strategic material selection for color consistency involves choosing high-grade base resins with consistent melt properties, UV-stable colorant systems, compatible processing additives, and certified suppliers providing batch-to-batch reliability. Premium materials increase costs 15-30% but deliver superior consistency while reducing waste from color-rejected products.

Base resin quality significantly impacts achievable color consistency. High-grade resins provide uniform melt characteristics that ensure consistent colorant distribution, while lower-grade materials may contain impurities or molecular weight variations creating processing inconsistencies.

ABS remains the standard choice for hair dryer housings, accepting wide Pantone color ranges with moderate UV stability when properly stabilized. PC materials offer high-temperature performance for transparent components but require UV protection packages to prevent yellowing degradation.

Material selection hierarchy includes:

• ABS: Economical housing material with good color acceptance

• PC: High-temperature transparent components requiring UV stabilization

• ABS/PC alloys: Premium blend offering superior heat resistance and color stability

• Specialized polymers: PCT/PET for extreme temperature applications

Advanced ABS/PC alloys used in premium hair dryers like Dyson and Laifen models provide improved heat resistance and impact properties while maintaining color stability to 120°C. These materials cost more but deliver consistent appearance under demanding operating conditions.

Colorant system selection balances performance requirements with cost considerations. UV-stable organic pigments provide excellent color strength but command premium pricing, while inorganic alternatives offer good lightfastness at lower costs for indoor applications.

Master batch suppliers play crucial roles in color consistency through certified formulations and technical support. Reputable suppliers provide guaranteed batch-to-batch consistency with documented quality systems and responsive technical assistance for optimization projects.

| Material Type | Hair Dryer Application | Color Stability Rating | Cost Premium |

|---|---|---|---|

| Standard ABS | Economy housings | Good | Baseline |

| PC | Transparent components | Excellent with UV package | +20-30% |

| ABS/PC Alloy | Premium housings | Excellent | +15-25% |

| Master Batch | All color applications | Varies by supplier | +10-25% |

How Do Leading Hair Dryer Manufacturers Implement Color Consistency Protocols?

Leading hair dryer manufacturers implement comprehensive color consistency protocols that integrate advanced technology, standardized procedures, and continuous improvement practices. These systematic approaches demonstrate best practices for achieving professional-grade color matching results.

Top manufacturers implement color consistency protocols through dedicated CMF (Colors, Materials & Finishes) teams, multi-angle spectrophotometer validation, lean engineering processes, ΔE tolerances <0.5 for outer covers, controlled-lighting verification under D50/D65/LED sources, inline spectrophotometer systems with closed-loop additive feeders, and family mold production ensuring component color matching.

Dyson’s CMF Engineering team, established in 2016, uses lean engineering principles and multi-angle spectrophotometers for validating each new colorway under multiple illuminants. Their red release buttons exemplify functional color coding that enhances user experience while maintaining strict ΔE tolerances below 0.5 for all visible surfaces.

Panasonic’s salon-grade manufacturing plants in Japan and Thailand implement inline spectrophotometer systems with closed-loop additive feeders that automatically adjust masterbatch dosing ±0.05% for every 50kg shot. Family molds produce handles and nozzles together, eliminating gate-to-gate color variations.

Implementation best practices include:

• Dedicated CMF teams: Specialized personnel managing color consistency programs

• Advanced measurement: Multi-angle spectrophotometers for effect pigments

• Process automation: Closed-loop control systems minimizing human error

• Documentation systems: Complete traceability from materials through finished products

Laifen’s high-speed dryer manufacturing employs ABS/PC alloys with proprietary anti-yellowing resin formulations. Mold cavity temperatures maintained at 90°C ensure uniform gloss while desiccant masterbatch processing enables recycled content use without color compromise.

Quality management systems integrate measurement data from multiple sources, creating comprehensive databases supporting statistical process control and continuous improvement initiatives. Regular supplier audits verify material consistency while process capability studies validate manufacturing performance.

Training programs ensure consistent application of color matching procedures across all shifts and production lines. Comprehensive education covers color science fundamentals, measurement techniques, and troubleshooting procedures for quality personnel and operators.

At Laifex, we implement these same professional color consistency protocols used by industry leaders. Our P1C high-speed hair dryer demonstrates our commitment to quality through precisely matched colors that maintain brand integrity across every production run, utilizing advanced ABS/PC alloy materials and closed-loop color control systems.

What Should Wholesalers Evaluate When Auditing Factory Color Consistency Capabilities?

Wholesalers must conduct thorough evaluations of factory color consistency capabilities to ensure their branded products meet customer expectations and maintain market reputation. Understanding critical audit criteria helps identify reliable manufacturing partners capable of delivering consistent results.

Wholesalers should evaluate factories based on NIST-traceable spectrophotometer calibration, ISO 3664-compliant lighting booths (SDCM ≤3), SPC records showing Cpk ≥1.33 for recent production lots, masterbatch traceability systems linking batch IDs to raw material COAs, desiccant dryer logs documenting moisture control <0.02%, and environmental controls maintaining 25±2°C production temperatures.

Equipment quality assessment begins with verifying spectrophotometer calibration certificates from NIST-traceable sources updated within 12 months. Professional facilities maintain multiple measurement devices with documented maintenance schedules and performance verification procedures.

Controlled-lighting booth evaluation requires confirmation of ISO 3664 compliance with D50 and TL84 illuminants providing SDCM ≤3 uniformity. These systems enable accurate visual assessment and metamerism detection under standardized conditions.

Critical evaluation criteria include:

• Measurement equipment: Calibrated spectrophotometers with maintenance records

• Process capability: SPC data demonstrating Cpk ≥1.33 performance levels

• Material traceability: Batch tracking systems linking components to source materials

• Environmental controls: Documented temperature and humidity management

Documentation review should examine corrective action reports for color-related non-conformances, with closure times under one week indicating effective problem-solving capabilities. Statistical process control records provide objective evidence of consistent performance over time.

Material handling assessment verifies proper storage conditions, desiccant dryer operation logs, and moisture control procedures for hygroscopic resins. These systems prevent color-shifting defects while maintaining material quality throughout production cycles.

Quality management system evaluation includes reviewing training records, work instruction documentation, and audit findings from previous assessments. Comprehensive systems demonstrate commitment to consistent quality delivery.

Sample evaluation programs should request products from multiple production runs representing normal manufacturing conditions rather than specially prepared demonstration parts. This approach reveals actual consistency performance under routine operating conditions.

| Audit Criterion | Acceptable Standard | Why Critical | Documentation Required |

|---|---|---|---|

| Spectrophotometer Calibration | NIST-traceable <12 months | Measurement accuracy | Calibration certificates |

| Process Capability | Cpk ≥1.33 last 3 lots | Statistical control | SPC charts |

| Environmental Control | 25±2°C, 45±5%RH | Stability assurance | Monitoring logs |

| Traceability System | Batch ID to raw material | Root cause capability | Database records |

What Emerging Technologies Are Revolutionizing Hair Dryer Color Consistency?

The hair dryer manufacturing industry is experiencing technological revolution through advanced quality control systems, artificial intelligence integration, and sustainable material innovations. These emerging technologies promise to enhance color consistency while reducing environmental impact.

Emerging technologies revolutionizing color consistency include LED factory lighting requiring spectral recalibration, inline AI vision systems with hyperspectral sensors detecting sub-0.3 ΔE variations, automated rejection systems reducing scrap by 25%, bio-based pigments with biodegradable carriers, and real-time color monitoring with instant process corrections preventing defective unit accumulation.

LED factory lighting retrofits create new challenges and opportunities for color consistency. While LED systems reduce energy consumption, their different spectral power distribution requires recalibration of ΔE limits and potential masterbatch reformulation to maintain retail color matching under LED illumination ranging from 3000-4000K.

Artificial intelligence vision systems combine high-resolution cameras with hyperspectral sensors to identify color variations below human perception thresholds. These systems automatically reject non-conforming products before assembly, significantly reducing waste while improving overall quality consistency.

Technology advancement areas include:

• Smart lighting: LED systems requiring new color calibration protocols

• AI vision: Hyperspectral sensors detecting minute color variations

• Process automation: Real-time corrections preventing drift accumulation

• Sustainable materials: Bio-based pigments reducing environmental impact

Real-time monitoring systems integrate multiple data sources including inline spectrophotometers, environmental sensors, and process parameters to predict color drift before it occurs. Predictive algorithms enable proactive adjustments that maintain consistency without production interruptions.

Bio-based pigment systems represent the future of sustainable manufacturing, offering non-toxic alternatives to traditional colorants while maintaining color fastness requirements. These systems require new stabilizer packages but support environmental sustainability goals increasingly important to consumers and brands.

Machine learning algorithms analyze historical production data to optimize color matching protocols automatically. These systems identify subtle relationships between process variables and color outcomes that human operators might miss, enabling continuous improvement in consistency performance.

The integration of Industry 4.0 principles creates connected manufacturing environments where color data flows seamlessly between equipment, quality systems, and enterprise planning platforms, enabling unprecedented visibility and control over color consistency processes.

Summary

Factory color consistency for branded hair dryers requires systematic integration of scientific color measurement (CIELAB/ΔE), advanced materials selection, precision injection molding controls, real-time quality monitoring, and comprehensive environmental management. Professional manufacturers achieve Cpk ≥1.33 through spectrophotometric measurement, family mold systems, and closed-loop process controls. Wholesalers should evaluate suppliers based on equipment calibration, SPC documentation, and demonstrated consistency performance across multiple production batches.

Ready to partner with a manufacturer who delivers professional-grade color consistency? At Laifex, we implement the complete range of advanced color control technologies discussed above, ensuring your branded hair dryers maintain perfect color matching across every production run. Browse our complete product range at Laifex.com and contact us today to discuss your specific color requirements and volume needs.