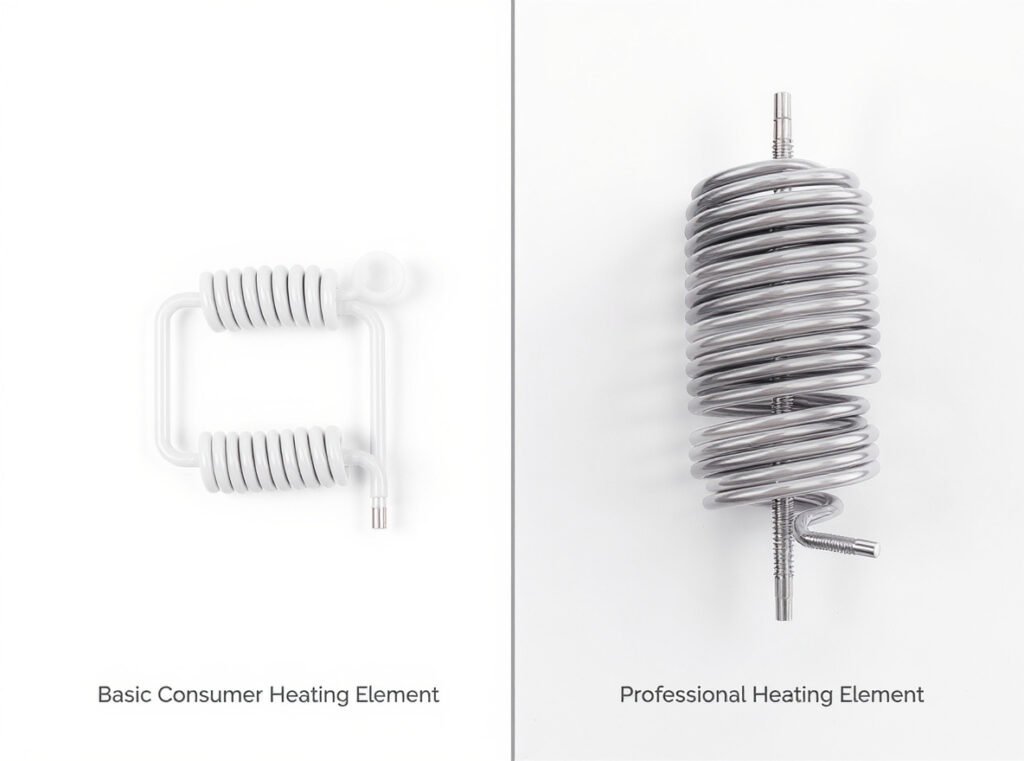

When choosing hair dryers for your business, understanding heating element differences can make or break your customers’ satisfaction and your profit margins. Professional-grade heating elements offer superior performance, durability, and results that consumer models simply cannot match.

Professional-grade heating elements feature 5-10 pounds more steel in construction, utilize brass drain valves instead of plastic, and incorporate superior thermostats with ceramic tank linings. They deliver up to 30% better energy efficiency and last 25+ years compared to consumer elements that typically operate for only 5-10 years.

Understanding these differences will help you make informed purchasing decisions that maximize your investment and customer satisfaction.

Table of Contents

ToggleWhy Does Heating Element Quality Matter for Your Business?

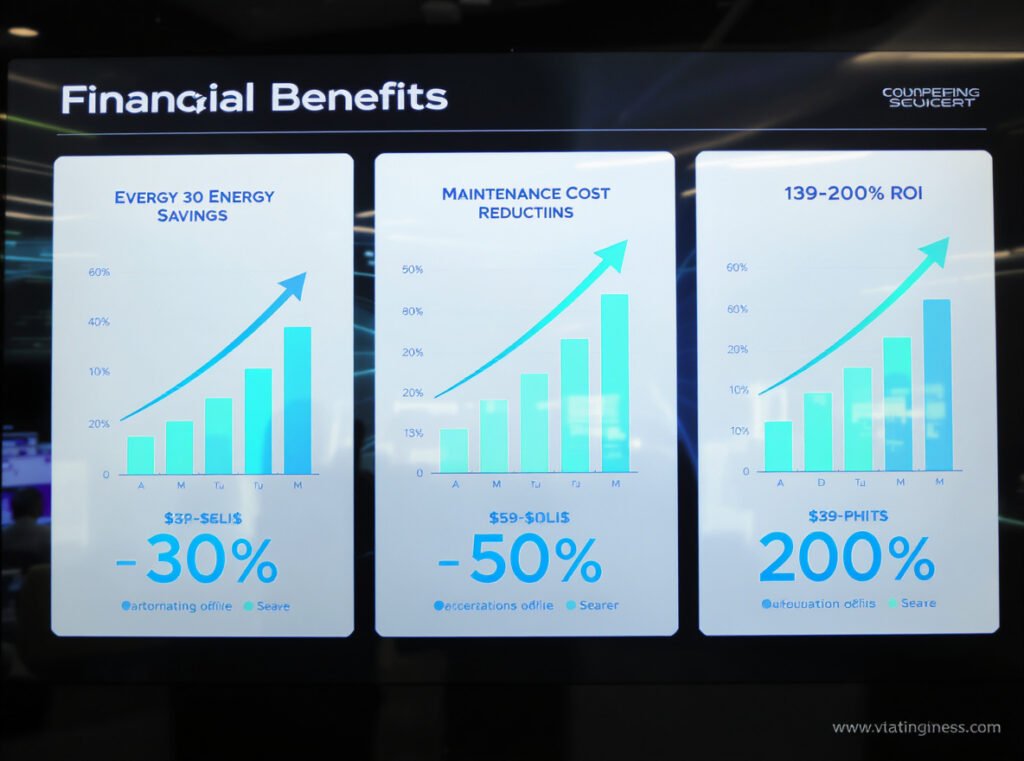

Every successful hair dryer distributor knows that heating element quality directly impacts customer retention and brand reputation. The financial benefits of professional-grade elements extend far beyond initial performance differences.

Professional heating elements reduce energy consumption by up to 30% while lowering maintenance costs by 50%. The return on investment typically ranges from 139% to 200% over a 10-year period, with annual cost savings of 6-9% through improved energy efficiency.

These elements provide consistent temperature control essential for business operations, preventing costly disruptions from equipment failures. Properties with energy-efficient heating systems experience 2.3% increases in rental value, making professional elements a strategic investment.

Professional heating elements deliver measurable business advantages:

• Reduced downtime through enhanced reliability

• Lower operational costs through energy efficiency

• Improved customer satisfaction with consistent performance

• Extended equipment lifespan reducing replacement frequency

The superior materials and construction quality justify higher initial costs through long-term operational savings and enhanced business reputation.

| Business Impact | Consumer Grade | Professional Grade |

|---|---|---|

| Energy Efficiency | Standard | 30% improvement |

| Maintenance Costs | Baseline | 50% reduction |

| ROI (10 years) | Limited | 139-200% |

| Annual Savings | Minimal | 6-9% cost reduction |

What Advanced Materials Make Professional Elements Superior?

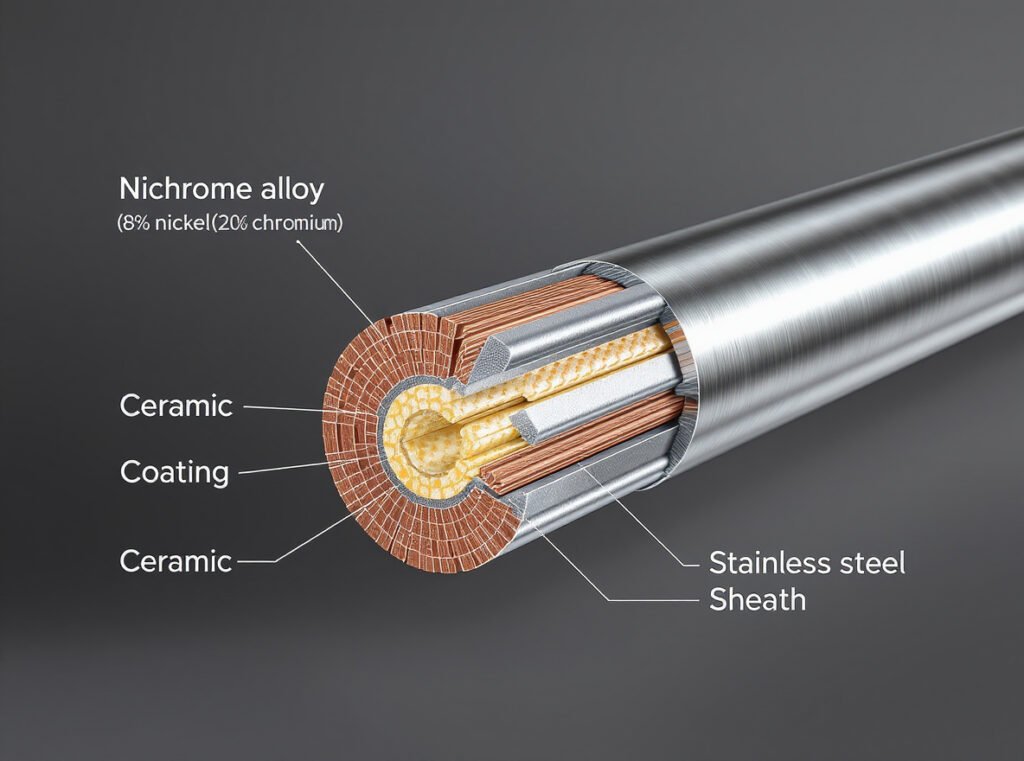

Professional heating elements utilize scientifically engineered materials that consumer models cannot match due to cost constraints. These materials directly impact performance, safety, and operational lifespan.

Nichrome alloys (80% nickel, 20% chromium) form the foundation of professional elements, offering superior electrical resistivity and corrosion resistance at temperatures up to 1,200°C. Iron-chromium-aluminum alloys (Kanthal) operate at temperatures up to 1,400°C with exceptional oxidation resistance.

The material engineering in professional elements represents decades of technological advancement:

Nichrome alloys provide the precise balance of electrical, thermal, and mechanical properties required for demanding applications. The 80/20 nickel-chromium composition delivers consistent performance across varying operational conditions.

Kanthal alloys excel in extreme temperature applications with excellent resistance to oxidation and sulfur attack. The protective aluminum oxide layer formation enhances durability and prevents rapid degradation.

Silicon carbide (SiC) heating elements operate effectively up to 1,600-1,700°C, offering exceptional thermal conductivity and mechanical strength for the most demanding applications.

Professional sheath materials include:

• Stainless steel with 13-26% chromium content for superior oxidation resistance

• Magnesium oxide (MgO) powder fill material for electrical insulation

• Ceramic tank linings instead of glass-lined alternatives

• Brass components replacing plastic parts in consumer models

Consumer elements typically use basic wire coils with standard ceramic coatings that lack the sophisticated metallurgy of professional alternatives.

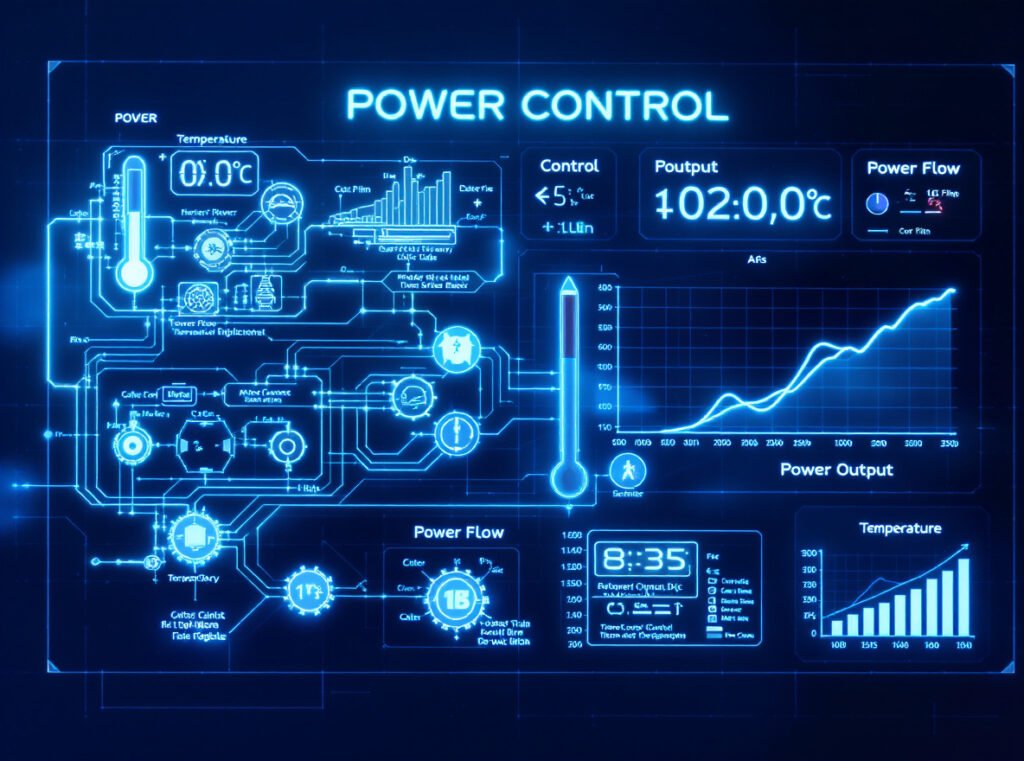

How Do Professional Elements Achieve Superior Power Control?

Power output management separates professional heating elements from consumer alternatives through sophisticated engineering and precise control mechanisms.

Professional elements demonstrate superior power density control, measured in watts per square inch (W/in²), using the formula: Power Output = (Voltage)² / Resistance. They maintain consistent resistance values across varying operational conditions with intelligent temperature control technology.

The engineering precision in professional elements enables optimal performance:

Heat transfer coefficient optimization follows the equation: Temperature (T) = (Power Input (P) / Heat Transfer Coefficient (h) × Surface Area (A)) + Ambient Temperature. Professional elements achieve superior thermal performance through engineered design specifications.

Temperature control sensors in professional systems achieve precise regulation without overheating or temperature fluctuations. This optimization reduces heat loss and improves overall energy utilization efficiency.

Power density management ensures consistent performance under varying load conditions. Professional elements maintain stable output while consumer alternatives experience significant fluctuations.

Surface area optimization maximizes heat transfer efficiency through advanced material properties and geometric design considerations.

• Consistent power delivery across operational temperature ranges

• Intelligent control systems preventing energy waste

• Optimized heat transfer coefficients for maximum efficiency

• Stable resistance values under thermal cycling

The sophisticated power management systems in professional elements justify their premium positioning through measurable performance advantages.

What Safety Systems Distinguish Professional Heating Elements?

Safety considerations become paramount when dealing with high-wattage heating elements, especially in commercial environments where liability and operational continuity matter.

Professional elements incorporate comprehensive safety protection systems including element skin temperature controls, process temperature control, earth leakage protection, and overload current protection. PTC (Positive Temperature Coefficient) technology provides self-regulating capabilities where electrical resistance increases as temperature rises.

Professional safety systems feature multiple protection layers:

Multiple safety interlocks monitor high element temperature, earth fault detection, and process over-temperature protection with emergency stop access. These systems prevent cascading failures that could damage equipment or create safety hazards.

PTC technology eliminates the need for external temperature controls by providing inherent self-regulation. As temperature increases, electrical resistance automatically increases, preventing overheating without additional thermostats.

Temperature monitoring systems include RTDs (Resistance Temperature Detectors) and thermocouples for monitoring element skin temperature, tube sheet temperature, terminal box temperature, and process fluid temperatures.

Pressure Safety Valves (PSV) provide additional protection for high-pressure operations, ensuring safe operation under extreme conditions.

| Safety Feature | Consumer Grade | Professional Grade |

|---|---|---|

| Temperature Controls | Basic single-point | Multiple advanced sensors |

| Self-Regulation | Manual controls | PTC automatic regulation |

| Earth Fault Protection | Limited/None | Comprehensive systems |

| Emergency Systems | Basic shut-off | Multiple safety interlocks |

Consumer elements often lack these sophisticated safety features to meet lower price points, creating potential operational and liability risks.

How Does Durability Compare Between Professional and Consumer Elements?

Durability differences become especially critical when calculating total cost of ownership and operational reliability for your business inventory.

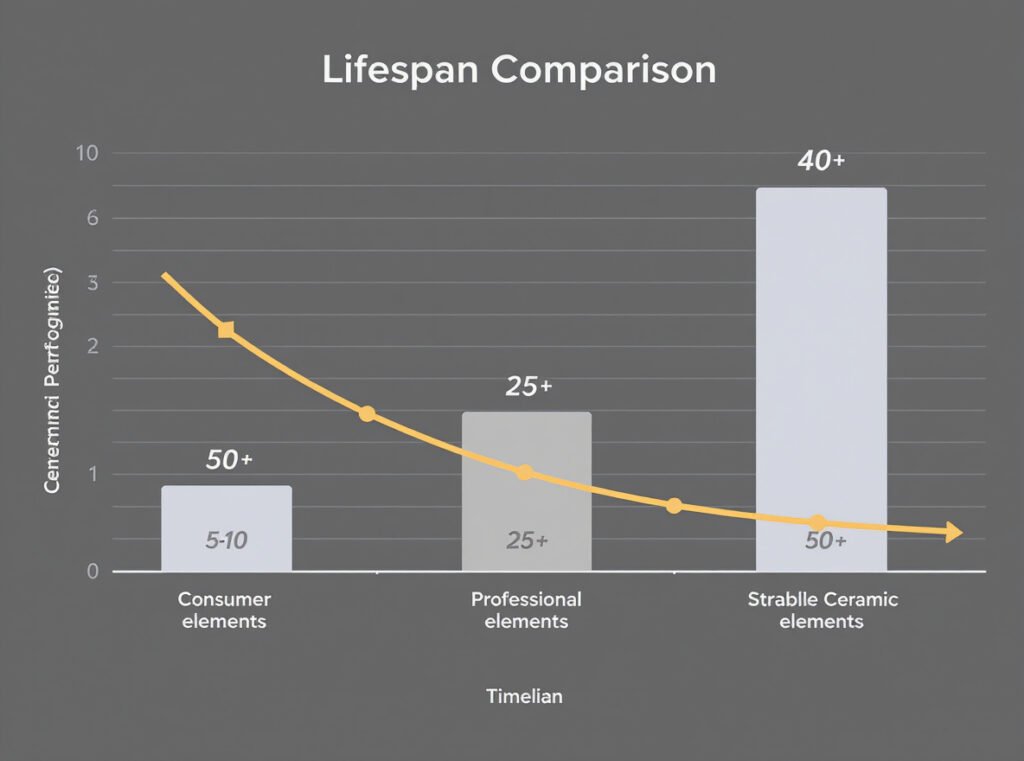

Professional heating elements last 25+ years with proper maintenance, while consumer-grade elements typically operate for 5-10 years. Silicon carbide heating elements in professional applications exhibit exceptional longevity, with ceramic materials lasting 40+ years under proper operating conditions.

The dramatic lifespan differences result from fundamental engineering approaches:

Life expectancy directly correlates to internal coil temperature, where professional elements maintain lower operating temperatures through superior design and materials. The work-hardening resistance prevents premature failure that plagues consumer elements.

Professional materials resist chromium diffusion and nickel concentration changes that cause embrittlement over thermal cycling. Consumer elements suffer from these metallurgical changes, leading to sudden failures.

Ceramic materials in professional applications demonstrate remarkable longevity through advanced material science. The protective aluminum oxide layer formation in Kanthal elements enhances durability compared to standard consumer materials.

Expected operational lifespans under typical usage:

• Consumer elements: 5-10 years with declining performance

• Professional elements: 25+ years with consistent performance

• Premium ceramics: 40+ years in optimal conditions

• Industrial applications: Extended service through robust construction

The superior durability translates to lower replacement costs, reduced maintenance intervals, and enhanced operational reliability that justifies the initial investment premium.

Which Professional Heating Technologies Should You Specify?

Selecting appropriate heating element technology requires evaluating temperature range requirements, material compatibility, and operational environment demands for your specific market applications.

For hair dryer applications, resistance wire elements (Nichrome) function effectively up to 1,200°C for general use, while ceramic elements handle extreme temperature requirements. Material compatibility considerations include resistance to reactive substances and operational environments.

Technology selection guidelines by application:

High-Performance Professional: Silicon carbide performs excellently in oxidizing atmospheres with superior thermal conductivity. Kanthal resists corrosive conditions while maintaining consistent performance across temperature ranges.

Commercial Applications: Nichrome alloys provide reliable performance with excellent electrical resistivity and corrosion resistance. The 80/20 nickel-chromium composition delivers consistent results under demanding conditions.

Extreme Temperature Operations: For temperatures above 2,000°C, graphite heating elements provide exceptional performance in vacuum and inert-gas environments. Molybdenum disilicide (MoSi₂) elements excel in extreme heat applications.

Selection criteria include:

• Watt density requirements for specific applications

• Operating temperature specifications and thermal cycling

• Heating medium characteristics and environmental conditions

• Expected duty cycles and operational demands

For our Laifex P1C high-speed hair dryer (https://laifex.com/p1c-hair-dryer/), we utilize advanced Nichrome alloy elements with ceramic enhancement technology that delivers professional-grade performance while maintaining competitive wholesale pricing for distributors serving diverse markets.

Summary

Professional-grade heating elements significantly outperform consumer alternatives through advanced materials like Nichrome alloys, superior safety systems with PTC technology, and extended 25+ year lifespans. The 139-200% ROI over 10 years, combined with 30% energy savings and 50% maintenance cost reduction, makes professional elements essential for serious hair dryer businesses.

Ready to upgrade your inventory with professional-grade heating technology? Browse our complete selection of high-performance hair dryers and discover how advanced heating elements can maximize your business success.

Looking to source professional-grade hair dryers with advanced heating technology? Contact Laifex today for wholesale pricing on our P1C model featuring professional Nichrome alloy elements. Our technical team can help you select the optimal heating technology for your target market and maximize your competitive advantage.